Sorted by date Results 1 - 18 of 18

Loan will support US plant capable of producing EV battery materials at the giga-scale. Toward the White House's goal of zero-emission vehicles making up half of all car sales in the U.S. by 2030, the U.S. Department of Energy has conditionally committed to lend $2 billion to Redwood Materials Inc. to support the expansion and construction of a battery recycling and manufacturing complex in Nevada. Announced on Thursday via the DOE Loan Programs Office, Redwood will use the...

Electric vehicles are a major player in the decarbonization of the global transport sector. The industry is under pressure to seek the shortest, most profitable route to a renewable future, which puts its most expensive asset – battery production – at risk of potentially redistributing rather than neutralizing carbon usage. Nowhere is this pressure more acute than in the growing demand for a more sustainable and scalable battery lifecycle. Due to roughly 15 years of ope...

In December, China implemented new export controls on graphite, further compounding trade tensions with the United States and other Western nations. This decision reinforces concerns over the fragility of the West's over-reliance on import monopolies and serves to intensify the ongoing search for alternative sources that would otherwise have been considered economically unattractive. Outside of its use in electric vehicle batteries, an application that is rocketing its...

Future product will comprise 20% recycled nickel, 20% lithium, 50% cobalt, and 100% copper for world's most sustainable EV battery. Last year, Redwood Materials Inc. partnered with Toyota Motor North America to create a closed-loop solution for electric vehicle batteries. Initially focused on the collection, testing, and recycling of Toyota hybrid EV batteries, the companies recently announced the next stage in their collaboration – utilizing Redwood's recycled materials as p...

The growing list of critical minerals and conflict elements like cobalt are drawing intense focus and demand for alternative sources. Investors and consumers are increasingly focused on the environmental, social and governance (ESG) credentials, provenance, and indirect emissions of these supply chains. If done right, prioritizing urban mining – specifically moving recycled materials upstream in supply chains – could provide cheaper domestic supply with a lower emissions foo...

Following up on plans to spread its roots into the world's fastest-growing electric vehicle market, Redwood Materials Inc. has acquired the leading European Union battery recycler, Redux Recycling GmbH. Located in Bremerhaven, on Germany's North Sea coast, Redux Recycling's facility is equipped to recycle up to 10,000 metric tons of lithium-ion batteries with a variety of chemistries. Centrally located within Europe and near the distribution center of the Bremerhaven Port,...

Critical minerals can be recycled from decades of e-waste The necessity of reclaiming waste as a means to curb the seemingly impossible material requirements of a renewable future is fostering a different kind of industry – urban mining. "When you're in the renewable energy space, you've got to think through the whole lifecycle – where will EV and lithium-ion batteries go when they are no longer useful? It can't be to a landfill. That's not responsible," said Graphite One Pres... Full story

From a small sprout to a mighty tree, Redwood Materials Inc. may share its roots with the Tree of Tesla but has grown into a pillar of stability in the realm of recycling amidst a time when electric vehicle battery materials are becoming increasingly difficult to source. This battery and e-waste startup's vision of creating a domestic supply through recycling has drawn nearly $2 billion in new investment to expand its operations in the U.S., spreading its own "Sequoian" roots...

Lithium is an indispensable element in the clean energy transition for several key reasons; like all alkaline metals on the periodic table, it has one more electron than it strictly needs, and this tendency to shed electrons makes it well-suited for passing them back and forth between cathode and anode, charging and discharging thousands of times without degradation. Pure lithium does not occur in nature, but traces are found throughout nearly all igneous rocks, mineral... Full story

Separating your plastics, paper, metals, and food waste has generally been a personal choice throughout most of modern recycling history. However, current demand for resources predicts we won't have enough to support net-zero carbon emissions by 2050. Hence, now is the best time for consumers to become educated and self-determined with their buying power, manufacturers to begin considering recycling as part of the initial design, and a new circular economy that resurrects a tr... Full story

There is nearly a $1 trillion chasm between where the United States' lithium battery supply chain is today and where it needs to be by 2035 in order to build the envisioned green energy future where electric vehicles are charged with low-carbon energy. Roughly 40% of this investment will need to go toward ensuring there is a plentiful supply of cobalt, graphite, lithium, nickel, and other battery materials. Simon Moores, CEO of Benchmark Mineral Intelligence and one of the... Full story

As part of its commitment to reduce its environmental footprint and achieve carbon neutrality by 2050, Toyota Motor North America is collaborating with Redwood Materials Inc. to create a sustainable, closed-loop battery ecosystem for its electrified powertrains. Toward this goal, Toyota and Redwood will explore a series of end-of-life battery solutions for Toyota's proposed battery ecosystem. The mission focuses not only on the collection, testing, and recycling of batteries...

After partnering together mid-2022, Volkswagen Group of America, Inc., has expanded its existing collaboration with Redwood Materials Inc. by adding Redwood recycling bins at participating Volkswagen dealerships to conveniently recycle rechargeable devices or lithium-ion batteries. "Volkswagen's goal is to provide more accessible and more sustainable electric mobility for American drivers," said Andrew Savvas, executive vice president, chief sales and marketing officer,... Full story

As recycling becomes more prominent in the restructuring of basically everything toward decarbonization and electrification, Redwood Materials Inc. announced its biggest move yet, a new battery materials campus in the heart of the "Battery Belt" just outside Charleston, South Carolina. Currently, anode and cathode components are not produced in North America, and battery cell manufacturers must source them via a 50,000-mile-plus global supply chain. As a result, U.S. battery... Full story

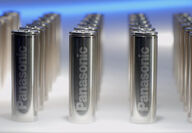

Cathode supply deal follows seal of approval from Argonne National Laboratory. Helping to offset the imbalance of demand to resources, battery recycler Redwood Materials Inc. will supply Panasonic cathode material for lithium-ion battery cell production at the electronic powerhouse's new Kansas plant, which is slated to begin production in 2025, marking the first time this material will be produced in North America at gigafactory scale. It is projected that in the next...

Redwood Materials Inc. has partnered with yet another auto giant, Volkswagen Group of America, Inc., to create a new circular supply chain for recycled Volkswagen and Audi electric vehicle batteries in the United States. After announcing a partnership with Toyota Motor North America in late June, it was not long before Volkswagen – which has already been taking steps to prepare for its end-of-life EV batteries for some time now – sought the California battery recycler to loc...

Redwood Materials Inc., an American battery recycling company that has been quietly prepping for an energy transition before it became a well-circulated buzzword, has already begun its own transition to the European market. Founded in 2017 by Tesla co-founder JB Straubel, this forward-thinking recycling company has rapidly climbed to a valuation of $3.8 billion as of September 2021. In a recent interview, Associated Press journalist Tom Krishner asked Straubel whether Redwood... Full story

While laying out an action plan to establish the national network of electric vehicle charging stations needed to keep pace with its ambitious goal of 50% of all vehicles sold in the United States being electric by 2030, the Biden administration reiterated that domestic battery manufacturing and critical minerals supplies are key aspects of the overall EV strategy. The White House is backing up this commitment to domestic battery supply chains with roughly $20 billion in loan... Full story