Sorted by date Results 1 - 7 of 7

One way to extend the range of an electric vehicle, or even get better gas mileage out of a conventional internal combustion automobile, is to lighten the load. NioCorp Developments Ltd. is working with automakers to develop strong and lightweight aluminum-scandium auto parts in the United States that will do just that. NioCorp has been advancing a strategy to commercially produce aluminum-scandium master alloy, which only needs a small dose of scandium to bolster the...

Powering a remote zinc mine located roughly 600 miles northwest of Anchorage, Alaska, is a Herculean task. Governments and industry have taken a particular interest in remote arctic mining locations, not only because of the region's vast mineral resources but also because of shipping routes that are opening through the ice due to climate change. Still, getting energy to those locations is extremely difficult. First, a tanker must transport diesel fuel to a port on the Arctic...

Rio Tinto, Fortune Minerals team up to recover critical minerals at Nico refinery in Alberta. To bolster the North American supply of critical minerals, global mining giant Rio Tinto and Canadian mine developer Fortune Minerals Ltd. are working together to improve the recovery of bismuth and cobalt from ore and waste streams. "We are committed to find better ways to provide the materials the world needs to grow and decarbonize," said Rio Tinto Kennecott Managing Director Nate...

Delegates agree on six actions to strengthen and diversify critical energy mineral supply chains. The rapid transition away from the fossil fuels that powered the world through the 20th century and toward lower-carbon sources such as wind and solar is creating enormous new demands for critical minerals and metals like cobalt, copper, lithium, and nickel. This interdependency was highlighted during the first-ever International Energy Agency Critical Minerals and Clean Energy...

Moving to seize opportunities presented by a rapidly emerging manufacturing sector in the cybersecurity industry, graphene maker HydroGraph Clean Power Inc. is teaming up with Kansas-based EMP Shield Inc., a leader in protecting devices from destructive interference caused by electromagnetic airwaves. Under the collaboration, the companies aim to develop advanced electromagnetic interference shielding products using HydroGraph's high-purity graphene. Electromagnetic interferen...

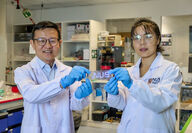

Gallium is a key ingredient of this self-healing and pliable circuit for next-generation wearables, other smart devices. Flexibility, durability, and efficiency are some of the key functions scientists are trying to narrow down for wearable tech, soft robotics, or smart devices. In comparison, there have been numerous advances in this field, but the recipe for something as pervasive as the cellphone has yet to meet the mark. That may change with a novel liquid metal circuit de...

Based on the success of its battery recycling trial, which showed improved recoveries of critical battery elements, higher metal content, and reduced use of reagents, thus paving the way for a higher-quality final product for its customers, Electra Battery Materials Corp. is extending processing of black mass at its refinery complex in Ontario, Canada. "Results from our plant-scale black mass trial continue to exceed our expectations," said Electra Battery Materials CEO Trent...