Sorted by date Results 1 - 25 of 52

REE recycler invests $25M in commercial processing and R&D facility. Advancing its mission to close critical loops in rare earth supply, Cyclic Materials Inc. has announced a $25 million (C$34 million) investment to establish North America's first rare earth recycling center – a pioneering 140,000-square-foot facility set to integrate commercial-scale magnet processing with cutting-edge research and development for a more secure, circular clean energy future. With attention i...

Modular system to unlock rare earths from waste to feed U.S. refineries. Building on earlier efforts to extract rare earth elements from coal waste, American Resources Corp. has introduced a modular, mobile leaching system designed to recover critical minerals from previously mined materials – transforming environmental liabilities into scalable, revenue-generating assets. "This is a pivotal moment for our country – one where we must, and will, break China's dominance ove...

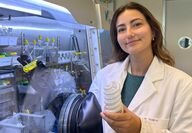

Launches sustainable platinum metals production at BC plant, maps global expansion. Vancouver, British Columbia-based pH7 Technologies has taken a major step toward commercializing a breakthrough technology that significantly reduces the environmental and energy costs of recovering platinum group metals (PGMs) from end-of-life catalytic converters that scrub harmful emissions from exhaust. On July 16, the critical and precious metals extractions startup announced that it has...

Cyclic to recycle rare earths from retiring fleet motors across North America. Leveraging a 270,000-vehicle micromobility fleet nearing retirement, rare earth recycler Cyclic Materials Inc. has joined forces with Lime to harvest and process the neodymium-iron-boron magnets from its soon-to-be decommissioned e-bike and scooter motors across North America, inaugurating the first large-scale magnet recycling program for shared electric vehicles and unlocking a new urban stream...

IDTechEx reports the data behind the strategy; can the U.S. learn from its ally? Critical material recovery in Europe is no longer a question of "if" but "when." The EU is rapidly building infrastructure to recover tens of thousands of tons of lithium-ion (Li-ion) battery metals and rare earth elements (REEs) by 2030. However, achieving full-scale material security will require more than just processing capacity – it will depend on effective collection and separation to e...

Non-binding letter outlines potential funding for Ontario facility. As part of a continued push to advance domestic critical minerals supply, the Government of Canada has issued a letter of intent outlining $20 million in proposed funding to support Electra Battery Materials' cobalt sulfate refinery in Temiskaming Shores, Ontario. "We are grateful to be working with the Government of Canada," said Electra Battery Materials CEO Trent Mell. "Today's announcement underscores...

New subsidiary secures $911K grant to process end-of-life materials. A newly surfaced player in critical mineral recycling, Electrified Materials Corp. has secured a nearly $1 million grant from the state of Indiana to expand its rare earth magnet and battery material recovery efforts – quietly adding another piece to American Resources Corp.'s growing supply chain. Best known for its ReElement Technologies subsidiary, American Resources has steadily built a foothold in critic...

American Resources scales REE and antimony refining, expands with Africa partnership. Less than a week after announcing its entry into antimony refining, American Resources Corp., through its subsidiary ReElement Technologies, made another major move in the critical minerals space. This time, by announcing weekly shipments of high-purity rare earth oxides, solidifying its position as the only U.S. producer capable of refining both heavy and light rare earth elements at...

Innovative mining company explores potential of recovering tech metal from aluminum plant in Quebec; province backs endeavor. In a move that could help fill the gap in supply left by China's ban on exports of gallium to the United States, Rio Tinto is investigating the potential of recovering this high-tech metal needed for computer chip manufacturing from its aluminum operations in Quebec. ''This new research and development project is destined to help strengthen the North Am...

Funding to support New York facility to recycle critical battery materials. Amid rising demand for domestic battery recycling solutions, Li-Cycle Holdings Corp. has secured a landmark $475 million loan from the U.S. Department of Energy to advance the development of its Rochester Hub project, a facility poised to become North America's first commercial-scale hydrometallurgical battery materials recovery center. Over the past few years, Li-Cycle has emerged as a leader in...

IDTechEx report examines potential of critical materials recovery from EVs to drive a circular economy by 2045. As the automotive industry shifts toward electrification, recycling end-of-life vehicles is becoming an increasingly important source of critical materials, potentially surpassing traditional mining. According to a recent report by IDTechEx, the recovery of valuable metals from electric vehicle batteries and motors is expected to generate over $100 billion annually...

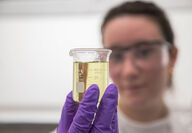

Rare earth elements (REEs) are essential building blocks for the world's electronics and a host of developing energy transition technologies. Found in smartphones, computers, screens, and batteries, they are essential in everything from smartwatches to wind turbines. This suite of 15 elements, however, are notoriously challenging to separate. Conventional processes are often chemical-heavy and energy-intensive, requiring multiple extraction and purification steps, which are sl...

Microsoft's Climate Innovation Fund invests in recycling REEs from hard drives. Signaling its commitment to a circular economy, Microsoft has made a notable endorsement by strategically investing in Cyclic Materials, a promising startup in advanced metals recycling. Announced July 16, this move by Microsoft's Climate Innovation Fund highlights the tech giant's interest in sustainable innovation, particularly in recycling rare earth elements (REEs) from computer hard drives....

Lithium battery recycling firm is resizing and reshaping its hub-and-spoke operations to overcome challenging financial landscape. Following the $75 million strategic investment from Glencore plc last week, which was aimed to alleviate some of the pressures the company is feeling due to the higher-cost environment, Li-Cycle Holdings Corp. announced an update on its situation and plans to right-size its recycling enterprise going forward. "Since embarking on our comprehensive...

Partnership with Pyxera successfully tested a "circular logistics" model to upcycle critical minerals from electronic waste. Following a successful pilot program at the end of last year in Tennessee, FedEx, Pyxera Global, and several other companies have launched the Circular Supply Chain Coalition (CSCC) to boost the domestic supply of critical minerals for new tech hardware in the United States by "mining" discarded consumer electronics. CSCC's vision is to strengthen and ex...

Company ramps up recycling facility, operates at over 115% capacity. In a triumph of innovation, American Battery Technology Company announced a groundbreaking milestone: its lithium-ion battery recycling facility has been operating steadily at over 115% of its designed capacity, showcasing the efficacy of its proprietary recycling technology. Established in 2011, ABTC began its journey with a handful of mining claims out of Nevada. Stemming from a former Tesla employee's ambi...

Supports future recycling leader toward ongoing facility construction. Almost two years after its initial $200 million investment from Glencore plc, Li-Cycle Holdings Corp. has announced a new $75 million strategic investment from the Swiss commodities trading and mining company to help the recycling company continue to position itself as a future leader in the production of critical battery materials. "We are pleased to secure an additional $75 million investment from...

Inching closer to a fully operational battery recycling and refining facility, Electra Battery Materials Corp. has utilized the last year to meticulously streamline, optimize, and improve its battery recycling trial, as well as the recovery systems for lithium, nickel, cobalt, and other critical minerals at its Ontario complex in Canada. "Throughout this 12-month demonstration operation, our team has continued to refine and optimize the processes resulting in successive...

Setting the bar for battery materials, American Resources Corp.'s ReElement Technologies announced that it has achieved an ultra-high purity of 99.96% battery-grade lithium carbonate from its unique technology developed in partnership with Purdue University. American Resources is a next-generation and socially responsible supplier of raw materials to the new infrastructure and electrification marketplace. Utilizing its patented multi-modal chromatography technology, developed...

A new study out of Chalmers University of Technology, Sweden, presents a possible new and efficient way to recycle metals from spent electric vehicle batteries that uses an organic compound found naturally in plants – oxalate. Before the push for clean energy or renewable technologies, methods to recycle metal operated much like manufacturing metal, melting it. However, due to the carbon-intensive impacts of smelters or foundries, cleaner solutions to recycling have e...

Commences domestic supply of critical battery materials at new Nevada facility in less than a year. Working tirelessly and expeditiously toward commercialization, American Battery Technology Company excitedly announced the operational start-up of its commercial-scale lithium-ion battery recycling facility in Nevada, implementing its first-of-a-kind lithium-ion battery recycling technologies at industrial scale. "We are excited to have achieved this major milestone and to now...

The growing list of critical minerals and conflict elements like cobalt are drawing intense focus and demand for alternative sources. Investors and consumers are increasingly focused on the environmental, social and governance (ESG) credentials, provenance, and indirect emissions of these supply chains. If done right, prioritizing urban mining – specifically moving recycled materials upstream in supply chains – could provide cheaper domestic supply with a lower emissions foo...

Based on the success of its battery recycling trial, which showed improved recoveries of critical battery elements, higher metal content, and reduced use of reagents, thus paving the way for a higher-quality final product for its customers, Electra Battery Materials Corp. is extending processing of black mass at its refinery complex in Ontario, Canada. "Results from our plant-scale black mass trial continue to exceed our expectations," said Electra Battery Materials CEO Trent...

Following up on plans to spread its roots into the world's fastest-growing electric vehicle market, Redwood Materials Inc. has acquired the leading European Union battery recycler, Redux Recycling GmbH. Located in Bremerhaven, on Germany's North Sea coast, Redux Recycling's facility is equipped to recycle up to 10,000 metric tons of lithium-ion batteries with a variety of chemistries. Centrally located within Europe and near the distribution center of the Bremerhaven Port,...

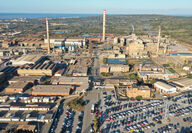

After announcing its plans for a recycling hub in Portovesme, Italy, through a partnership with Glencore, Li-Cycle Holdings Corp. has followed up with the steps needed to begin establishing a centralized locale for battery recycling in Europe's Bel Paese. "The planned Portovesme Hub is a landmark project for Europe's battery recycling industry and is expected to be the largest source of recycled battery-grade lithium on the continent," said Li-Cycle Executive Chair Tim...