Sorted by date Results 1 - 24 of 24

Following a recent strategic collaboration at the beginning of August, RecycLiCo Battery Materials Inc. and Nanoramic Laboratories announced the results of their testing, demonstrating both companies' technologies can be used to support the goal of optimizing the complete life cycle of lithium-ion batteries. With Nanoramic contributing its Neocarbonix lithium-ion battery electrodes and RecycLiCo providing its proprietary lithium-ion battery recycling process, the...

Critical minerals can be recycled from decades of e-waste The necessity of reclaiming waste as a means to curb the seemingly impossible material requirements of a renewable future is fostering a different kind of industry – urban mining. "When you're in the renewable energy space, you've got to think through the whole lifecycle – where will EV and lithium-ion batteries go when they are no longer useful? It can't be to a landfill. That's not responsible," said Graphite One Pres... Full story

Separating your plastics, paper, metals, and food waste has generally been a personal choice throughout most of modern recycling history. However, current demand for resources predicts we won't have enough to support net-zero carbon emissions by 2050. Hence, now is the best time for consumers to become educated and self-determined with their buying power, manufacturers to begin considering recycling as part of the initial design, and a new circular economy that resurrects a tr... Full story

Joining hands toward the stable supply of critical battery materials, RecycLiCo Battery Materials Inc. announced it has entered into a 50-50 joint venture with Zenith Chemical Corp. to build a 2,000 metric ton per year lithium-ion battery recycling plant in Taiwan. Since 2016, RecycLiCo has facilitated up to 100% extraction of valuable battery materials from nickel-manganese-cobalt and now lithium-iron-phosphate cathode chemistries. As all these battery chemistries contain...

Adapting to a future of renewable energy, trendsetters are focusing on recycling lithium-ion batteries to create a more efficient repurposing of one of the most vital and important technologies of today and possibly the future. Lithium-ion batteries have been around for decades but as we see a forward push for an electric future, the demand has changed to necessity. Global climate concerns, finite resources and the sheer growth of technology that requires mobile energy all... Full story

Shortly after signing a memorandum of understanding with Korean electronics manufacturer Sonid Inc., RecycLiCo Battery Materials Inc. announced that a Korean manufacturer used cathode material upcycled with the RecycLiCo to create battery cells that are comparable to those made with virgin cathode materials. According to RecycLiCo, the unnamed Korean cathode manufacturer reported that the battery cells using its recycling-upcycled nickel-manganese-cobalt oxide (NMC811)...

Battery recycling company RecycLiCo Battery Materials Inc. signed a memorandum of understanding with Korean electronics manufacturer Sonid Inc. signifying the first steps toward a potential commercial joint venture or licensing arrangement of the company's recycling technology. Outlining the strategic partnership and business framework for establishing a lithium-ion battery recycling facility, both companies aim to leverage their strengths for commercial collection, pretreatme...

RecycLiCo Battery Materials Inc. announced it has successfully closed the lithium-ion battery supply chain loop with its patented recycling and upcycling process. Closed-loop battery recycling is a method of recycling that aims to re-use all materials from an original discharged battery and re-purpose them into a new version of the same battery. This method also represents an important shift from a linear economy to a circular economy. Using the company's battery-ready...

Manganese-rich battery cathode recipes could stretch the other ingredients While not as talked about as other battery ingredients such as cobalt, lithium, and nickel, manganese is an important stabilizing ingredient in the cathodes of the nickel-manganese-cobalt lithium-ion batteries widely used in electric vehicles and electronics. "Their composition helps determine how long you can talk on the phone, how far you can drive an electric car, how fast a battery can recharge and... Full story

RecycLiCo Battery Materials Inc., in partnership with Kemetco Research Inc., has announced over 99% lithium recovery from its lithium-iron-phosphate (LFP) battery cathode materials process during bench-scale tests. Since 2016, RecycLiCo has facilitated up to 100% extraction of valuable battery materials from nickel-rich, manganese-rich, cobalt-rich, and now LFP cathode chemistries. As all these battery chemistries contain lithium, which has seen a more than 350% increase in pr...

After several months of waiting, RecycLiCo Battery Materials (previously American Manganese) has announced the results of a life cycle assessment for its lithium-ion battery recycling-upcycling RecycLiCo process. Conducted by London-based and globally recognized sustainability consultancy Minviro Ltd., the life cycle assessment is a standardized, scientific method for quantifying the direct and embodied environmental impacts associated with the RecycLiCo process. By...

American Manganese reports that it has delivered NMC-811 (nickel-manganese-cobalt) cathode precursor material samples produced with its RecycLiCo technology to third-party collaborators in North America, Europe, and Asia. "We are maintaining an active collaboration with players in the growing battery industry with our continuous lab-scale research, while we work in parallel to prepare our demonstration plant for scaled-up and continuous operations," said American Manganese...

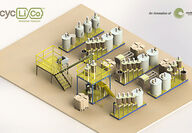

With the vision of commercializing its efficient and environmentally sound RecycLiCo lithium-ion battery cathode recycling process, in tandem with the growing need being driven by the rapid transition to electric mobility, American Manganese Inc. is readying for the construction of a plant to demonstrate this technology to potential strategic partners. "With multiple patents, technical publications, and rigorous testing, American Manganese sets itself apart with its...

Beyond simply recycling lithium-ion battery materials to be fed into supply chains, American Manganese Inc. is demonstrating that its RecycLiCo process can upcycle the black mass from spent batteries into new cathode material ready to go directly back in new cells. In the lithium-ion battery recycling process, black mass is a powdery material that is produced by crushing or shredding the electrodes after the casing and other ancillary parts have been removed from spent...

To steer away from using expensive and oft controversial cobalt, electric vehicle and lithium-ion battery manufacturers have brewed up new recipes with higher percentages of more abundant nickel and manganese for their newer generation cells. "Modern lithium-ion battery cathode chemistries have rapidly evolved to having less cobalt and more nickel or manganese materials, which does not reflect the cathode chemistries of older batteries approaching their end-of-life," said...

American Manganese Inc. has entered into a preliminary agreement to develop a lithium-ion battery cathode recycling facility alongside a battery gigafactory being developed in Italy by Italvolt. Founded and led by Lars Carlstrom, a pioneer industrialist in the automotive sector with more than 30 years of experience, Italvolt is advancing the development of a battery factory in Scarmagno, a northern Italian town about 65 miles west of Milan. The gigafactory is to be built at...

American Manganese Inc. has awarded Kemetco Research Inc., a leading metallurgical laboratory based in British Columbia, C$2.7 million to develop a 500-kilogram-per-day demonstration recycling plant and the design for a five-metric-ton-per-day commercial recycling plant that utilizes American Manganese's patented RecycLiCo process. Developed under a partnership with Kemetco, RecycLiCo is a process to recover cobalt, lithium, nickel, manganese, and aluminum from the cathodes...

Recently, American Manganese Inc., inventor of the patented RecycLiCo closed-loop lithium-ion battery cathode recycling process was awarded the Solar Impulse Efficient Solution Label, joining the ranks of positive impact businesses to protect the environment and is awarded to serve as a label for clean and profitable solutions. "We are pleased that our RecycLiCo process was awarded the Solar Impulse Efficient Label," said American Manganese President and CEO Larry Reaugh....

American Manganese Inc. Sept. 4 announced further improvements to the design and capacity of its RecycLiCo pilot plant, which recovers cobalt, lithium, nickel, manganese, and aluminum from lithium-ion cathode material. In addition to the growing opportunity to recycle spent lithium-ion batteries, scrap from the rapidly increasing number of battery megafactories provides an immediate source of cathode material in need of recycling. According to recent forecasts by Benchmark...

Recycling metals from spent lithium-ion batteries and rare earths from outmoded computers play a vital role in the United States reclaiming its critical mineral independence, according to Secretary of Energy Dan Brouillette. "Until our country can start mining and refining more of these materials or develop commercially viable substitutes, we must recycle as much critical mineral and REE content as we can from existing products," Brouillette penned in an editorial recently...

American Manganese Inc. has launched tests focused on upgrading and expanding its RecycLiCo pilot plant, which recovers cobalt, lithium, nickel, manganese, and aluminum from the cathodes of spent lithium ion batteries. American Manganese's revolutionary process and optimistic goal of reclaiming valuable critical minerals from lithium-ion batteries for reuse by the energy sector captured headlines earlier this year. With nearly 100% of valuable cathode metals being reclaimed...

American Manganese Inc. and Voltabox of Texas Inc. are in talks to utilize American Manganese's patented process to recycle the cathode materials in lithium-ion batteries produced by Voltabox. Voltabox manufactures lithium-ion battery systems for industrial applications such as electric buses, mining and construction equipment, agricultural machinery forklifts, and other warehouse equipment. Looking beyond the service life of the industrial batteries it produces, Voltabox has...

American Manganese Inc. Feb. 20 announced that its patented RecycLiCo process recovered up to 99.72% pure nickel-cobalt-manganese products generated from disassembled electric vehicle battery packs provided by a member of the U.S. Department of Energy Critical Materials Institute. The idea behind RecycLiCo emerged as an evolution of American Manganese's research into an efficient means of recovering manganese metals from relatively low-grade mineralization at its Artillery...

Reminiscent of America's gilded age, the world is priming itself for a new era of technology and energy centered on the electricity that sparked the imaginations of visionaries such as Nikola Tesla and Thomas Edison. This new era, however, sets aside more than a century of burning fossil fuels in favor of new clean sources of the electricity that will power human innovation into the 21st century and beyond. Solar, wind, hydro, and geothermal are but a few of the methods... Full story