Sorted by date Results 326 - 350 of 605

The largest-ever investment by an automaker into a battery materials mining company. To strengthen its domestic supply of the materials going into the batteries for its expanding lineup of electric vehicles, General Motors is investing $650 million toward the development of Lithium Americas Corp.'s Thacker Pass lithium mine in northern Nevada. Considered to be the largest known lithium deposit in the United States, Thacker Pass hosts 16.1 million metric tons of lithium...

As technology begins to enter the realm of 1990s-era science fiction, researchers from Soft Machines Lab at Carnegie Mellon University have developed a miniature shapeshifting robot that can liquefy itself and reform – basically a prototype of Skynet's cool but terrifying T-1000 robot in "Terminator 2". With assistance from Sun Yat-sen University and Zhejiang University, this liquid metal robot is based on gallium that has been embedded with magnetic nanoparticles. Since g...

Tesla's 140 GWh plant will produce batteries for 1.5M EVs per year; need globally significant mineral supplies. Tesla Inc. set the standard for giga-scale lithium-ion battery manufacturing with the startup of its 35 gigawatt-hour-per-year Gigafactory in Nevada in 2016. Now, the pioneering company is setting a new benchmark for electric vehicle battery production with a massive 100 GWh expansion of its world-changing factory. The news that Tesla has committed to investing heavi...

Stepping up to the plate in the contest for battery recycling, American Resources Corp. reported its subsidiary, ReElement Technologies, has produced greater than 99.9% lithium with its patented recycling technology. "Lithium refining in a cost effective and environmentally sensitive manner is the key to the domestic auto and electrification industry," said ReElement Technologies COO Jeff Peterson. "We applaud our team for exceeding our initial target results in producing...

In possibly one of the most significant years for nuclear since its advent, several nuclear energy milestones were achieved in 2022. Kicking off the year with a corollary incentive program to attract interest in this waning utility with enormous potential to provide clean, low-carbon energy, President Joe Biden signed into law the Inflation Reduction Act. This bill included a sizable aspect to benefit present and future nuclear facilities, even so much as providing a $15 per...

Enters deal with Element 25 for battery-grade manganese from Australia mine. In a move to secure an oft overlooked lithium-ion battery ingredient, Stellantis has cut a deal with Australia-based Element 25 Ltd. to supply a high-purity manganese product that the global automaker needs for the battery packs that power its growing line of electric vehicles. Element 25 plans to mine manganese from its Butcherbird deposit in Western Australia and ship a concentrate to a processing...

REIA urges EU to secure rare earth supplies to ensure adequate battery materials to meet 2030 EV targets. Securing an adequate supply of magnet rare earths to help make the most out of the highly competitive lithium battery materials should be an essential element of the European Union's electric vehicle strategy, according to the Rare Earth Industry Association. REIA delivered this message in response to the European Commission's call for input on the proposed European... Full story

Being supported by a $200 million grant from the U.S. Department of Energy's Battey Materials Processing and Battery Manufacturing initiative, General Motors has partnered with battery manufacturer Microvast to develop specialized electric vehicle battery separator technology along with a coinciding plant. Separators are safety-critical EV battery components that serve to separate the anode from the cathode, allowing ion transfer. Contributing its cutting-edge separator and... Full story

To seize upon a once-in-a-century opportunity to leverage Canada's already world-class mining sector to supply the minerals and metals needed to build the clean energy future, Ottawa has unveiled a strategy backed by a $3.8 billion (US$2.8 billion) investment to bolster the resiliency of critical mineral supply chains in the northern nation. Ottawa began positioning Canada as a major player at the front end of the emerging green energy supply chains with a 2021 list of 31... Full story

Rare tellurium has emerged as vital metalloid in next-gen solar, solid-state batteries. From longer-range electric vehicle batteries to long-lasting solar panels that efficiently charge those EVs with sunshine, tellurium is quietly becoming one of the most important energy metals that most people have never heard of. "It has flown largely under the radar, even though it's essential for cadmium-telluride solar panels and new lithium-tellurium batteries that could revolutionize... Full story

As recycling becomes more prominent in the restructuring of basically everything toward decarbonization and electrification, Redwood Materials Inc. announced its biggest move yet, a new battery materials campus in the heart of the "Battery Belt" just outside Charleston, South Carolina. Currently, anode and cathode components are not produced in North America, and battery cell manufacturers must source them via a 50,000-mile-plus global supply chain. As a result, U.S. battery... Full story

5 MWh battery designed by WAE for Liebherr haul truck charges in only 30 minutes. Australian iron ore miner Fortescue has received what is likely the largest electric vehicle battery in the world – a 1.4 megawatt-hour behemoth designed to power a 240-metric-ton mining haul truck it is developing in partnership with equipment manufacturer Liebherr. This massive 15-metric-ton battery – measuring a whopping 11.8 feet (3.6 meters) long, 5.2 feet (1.6 meters) tall, and 7.9 fee... Full story

Deepens alliance with Solid Power to commercialize next-gen cell tech. Under an expanded joint development agreement, BMW Group and Solid Power have added a research and development license as a basis for their common next steps, showing how much the luxury car maker believes in this next-gen technology of solid-state batteries. Spun out of a program at the University of Colorado in 2011, Solid Power is a U.S.-based battery developer that has been advancing solid-state...

Acquires land for EV battery factory in Lithium Valley. After months of searching for the ideal locale for a gigafactory capable of producing enough lithium-ion batteries for 650,000 electric vehicles per year, Statevolt has found a 154-acre site that can plug into the low-carbon energy and lithium being produced in the Salton Sea area of Southern California. "We have worked hard to find a suitable location to accommodate our vision and keep us near to our partners," said...

Seeking to achieve the next echelon of battery, Solid Power announced it has been awarded US$5.6 million in funding from the U.S. Department of Energy to continue developing its ground-breaking solid-state battery technology, which could significantly help lower the price of batteries across the board. Spun out of a program at the University of Colorado in 2011, Solid Power is a U.S.-based battery developer that specializes in solid-state, sulfide-based electrolyte technology...

Battery recycling company RecycLiCo Battery Materials Inc. signed a memorandum of understanding with Korean electronics manufacturer Sonid Inc. signifying the first steps toward a potential commercial joint venture or licensing arrangement of the company's recycling technology. Outlining the strategic partnership and business framework for establishing a lithium-ion battery recycling facility, both companies aim to leverage their strengths for commercial collection, pretreatme...

To lower the carbon footprint of its electric motors and other products that play a major role in allowing mining and many other sectors of the global economy to then lower their carbon footprint further, ABB is building a strategic partnership with Swedish mining and smelting company Boliden for low-carbon copper. Copper is a vital material for manufacturing the electrical equipment that is playing an increasingly important role in industrial applications that are...

Exploring new chemistries to reduce the necessity for critical metals needed for renewable energy, especially in the form of batteries, Oak Ridge National Laboratory has developed a method for producing lithium-ion batteries without the need for cobalt. With the future expectantly being powered with batteries, all walks of studious life have been knuckling down to improve a nearly half-century-old technology that, until recently, was good enough – given the imperative need t...

Enters deal for battery-grade nickel sulfate to be produced in Canada's new Battery Valley. In a deal that helps General Motors meet its electric vehicle ambitions and further solidifies Canada as the go-to North American source for low-carbon battery materials, the American automaker has cut a deal for the long-term supply of battery-grade nickel sulfate from a plant Vale Canada Ltd. is building in Quebec's emerging Battery Valley. "This new agreement with Vale reinforces...

Demonstration of Cat 793 Electric mining truck; new mine site of the future to be built at Tucson test site. With executives from some of the world's largest mining companies on hand to witness the historic event, Caterpillar Inc. carried out its first demonstration of a battery electric 793 large mining truck prototype at the heavy equipment company's proving grounds south of Tucson, Arizona. Roughly as tall as a two-story building and capable of carrying nearly 500,000...

USGS to carry out Earth MRI scan of lithium-rich areas of western states. Building upon its successful scans of the United States for potential sources of minerals critical to everything from smartphones and kitchen gadgets to the electric vehicles and wind turbines powering the renewable energy future, the U.S. Geological Survey announced it is investing $1.45 million for Earth Mapping Resources Initiative programs in Nevada and Oregon. Under the cleverly named Earth MRI...

Energy-dense, stable ceramic lithium battery electrolyte offers new use for a plentiful rare earth element. In what could be a win-win discovery for the future of long-range electric vehicles and the rare earths mining sector, engineers at California-based American Elements have invented a ceramic electrolyte material for use in solid-state lithium-sulfur batteries. Lithium-sulfur batteries can store somewhere between two and five times as much energy by weight than the curren...

Furthering its climate goals and hoping to continue strengthening the nation's battery supply chain, the Biden administration has allotted $74 million to advance technologies and processes for the recycling and reuse of electric vehicle batteries. The number of EVs on the road since Biden moved into the Oval Office has tripled and the demand for critical battery minerals, such as lithium and graphite, is projected to increase by as much as 4,000% in the coming decades....

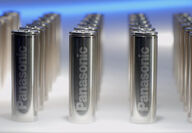

Cathode supply deal follows seal of approval from Argonne National Laboratory. Helping to offset the imbalance of demand to resources, battery recycler Redwood Materials Inc. will supply Panasonic cathode material for lithium-ion battery cell production at the electronic powerhouse's new Kansas plant, which is slated to begin production in 2025, marking the first time this material will be produced in North America at gigafactory scale. It is projected that in the next...

A team of researchers at Pennsylvania State University has developed a technology that enables electric vehicle batteries to obtain a full charge in just 10 minutes. The breakthrough in EV battery design, reported in the Oct. 12 edition of the journal Nature, produced a record-breaking combination of a shorter charge time and more energy acquired for a longer travel range. "The need for smaller, faster-charging batteries is greater than ever," said Chao-Yang Wang, the William...