Sorted by date Results 1 - 25 of 32

Taps global supply chain to deliver first trolley assist for 360-tonne mine trucks in the high Andes. Nearly three miles above sea level in Chile's Tarapacá region, a newly installed electric trolley system is helping Liebherr haul trucks lug 800,000 pounds of copper ore out of the Collahuasi mine. Owned and operated under a partnership between Anglo American, Glencore, and Japan Collahuasi Resources B.V., Collahuasi produces more than 550,000 metric tons (1.2 billion lb) of c... Full story

Haul truck designed to transition alongside mining clients' net-zero strategies, paired with trolley-assist at Boliden's Aitik copper mine in Sweden. As mining companies advance along diverse paths toward net-zero operations, Komatsu has adopted a power-agnostic strategy that allows its haulage equipment to evolve in parallel with its customers' decarbonization timelines. In a major milestone along this path, Komatsu and Swedish mining and smelting company Boliden have... Full story

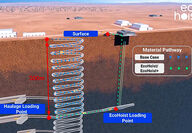

Innovative ore haulage system offers substantial cost and emissions savings for expanding an Olympic Dam-sized underground mine. A recent analysis backed by BHP confirms that the innovative EcoHoist ore haulage system offers a cost-effective and lower-emissions alternative for expanding underground mines to meet the rising global demand for copper and other energy-transition metals. Commissioned by BHP's Think and Act Differently initiative – a program aimed at accelerating i...

Largest-ever Sandvik BEV order will increase sustainability at next-gen Hermosa mine. In a landmark step toward sustainable U.S. critical mineral production, global mining company South32 Ltd. has ordered the largest fleet of battery-electric mining vehicles ever delivered by Sandvik. The zero-emissions trucks, loaders, drills, and bolters will support the development of Hermosa, a next-generation underground zinc-manganese-silver mine being built in Arizona's Patagonia...

Over $9M in battery-electric vehicles to be delivered to Canadian underground mine. Epiroc AB has secured a major order from Hudbay Minerals Inc. for a fleet of battery-electric vehicles (BEVs), including drilling rigs, loaders, and haulers, to be deployed at the Lalor mine in Manitoba, Canada, marking a significant step in Hudbay's electrification journey by enhancing productivity, reducing emissions, and cutting operational costs. "We are happy to support Hudbay Minerals as...

Partnering to develop trolley assist for reduced emissions in underground mines. To bring the electric mine of the future one step closer to reality, global mining equipment manufacturer Epiroc and electrification technology leader ABB have joined forces to develop a trolley system to assist ore-laden haul trucks on their climb out of the depths of underground mines. "The decarbonization of mine haulage fleets is becoming increasingly pressing as we look towards 2030...

Fast chargers aim to begin electrifying heavy mining operations by 2025. As mining shifts toward decarbonization, Fortescue is taking steps to electrify its operations with a 6-megawatt (MW) fast charger test unit, backed by funding from the Australian Renewable Energy Agency (ARENA) – a project that aims to revolutionize charging technology for heavy mining equipment, with the eventual deployment of 250 fast chargers across its iron ore operations by the end of the decade. F...

Case study shows innovative ore haulage system improves financial returns while lowering CO2 emissions at underground mines. Lowering carbon dioxide emissions and operating costs while also increasing productivity and profits are high on the priority list for modern mining companies. A comprehensive case study completed by EcoHoist, in conjunction with Mining One and ABB Hoisting Australia, indicates that the Australia-based mining tech company's innovative solution for the... Full story

Company leverages decades of experience to offer sustainable mining equipment and technologies. With global mining companies focused on minimizing their environmental footprint while maximizing the efficiency and profitability of producing the minerals needed to build a sustainable future, Komatsu will be showcasing its latest electrification solutions at MINExpo 2024 in Las Vegas, Nevada, from Sept. 24 to 26. Put on by the National Mining Association every four years,... Full story

BHP, Rio Tinto, Komatsu, and Caterpillar forge an alliance to accelerate deployment of battery-electric haul trucks. With all paths to net-zero-emissions mining leading through the ability to move rock without emitting carbon, two global mining companies are teaming up with two of the world's largest heavy equipment manufacturers to accelerate the development and deployment of battery-electric haul trucks. This landmark collaboration between BHP, Rio Tinto, Komatsu, and...

Scoping study finds implementing system could significantly reduce costs, time, and footprint in one fell swoop. In the pursuit of a domestic supply of the rare earths and other minerals critical to the United States, NioCorp Developments Ltd. has unveiled the results of a scoping study that demonstrates that the implementation of a Railveyor ore haulage system has the potential to reduce the carbon footprint, costs, and the time it takes to get to full production at its Elk... Full story

Zero-carbon underground mines of the future take step closer to reality with first electric truck trolley system. Boliden, Epiroc, and ABB are each known for pushing the envelope of mining innovation and electrification. Now, these companies have pooled their expertise into installing the first fully battery-electric truck underground trolley system on an 800-meter-long test track within Boliden's Kristineberg mine in northern Sweden. "Over the past three years, we have...

Installing fuel cells in more than 400 mining trucks for Anglo American. Only two months after a $1.5 billion transaction that transformed First Mode from a Seattle-based space mission engineering startup into a clean-energy subsidiary of global mining company Anglo American, the clean-energy firm is already busy retrofitting massive mining trucks with hydrogen fuel cells produced by Ballard Power Systems. Given First Mode's rapid ascent in the clean energy space, it is...

Aussie tech company develops innovative on-the-go charging system for electric mining trucks; collaborating with Hitachi Energy to enhance system. The quest for net-zero carbon emissions has mining companies and heavy equipment manufacturers brainstorming on innovative ways to electrify mining trucks often designed to haul hundreds of tons of rock per load. A dynamic charging system developed by Australia-based BluVein offers a solution that can be retrofitted to all brands...

Works with ABB to develop prototype that seldom needs a recharge due to innovative trolly assist and regenerative braking system. Heavy equipment staple Hitachi Construction Machinery Co. and electrification and automation leader ABB Ltd. have reached a milestone in their collaboration to develop a battery-powered electric mining haul truck that never needs to break for a recharge. Under development since 2021, with the goal of meeting the growing demand for reducing...

With no Plan(et) B, Wabtec is pushing ahead with tech to electrify trains and trucks for net-zero emissions mines. From electric trains delivering Western Australia iron ore to the next generation of zero-emissions mining trucks, Wabtec Corp. is committed to providing the decarbonizing electrification solutions that will allow the mining industry to achieve net-zero emissions by 2050. "What we are working on today is making sure that all of our solutions are geared towards... Full story

Starting this year, Swedish mining group Boliden will begin incorporating heavy battery-electric trucks into its underground transport fleet, beginning with two vehicles from Volvo Trucks. Diesel engines are a major contributor to carbon dioxide emissions and hydrocarbons in underground mines – this poses a safety challenge that must be managed to ensure the health of below-ground miners. Diesel exhaust also increases the carbon footprint of mining companies seeking to r...

To build electric mining equipment with potential to offer clean energy benefits that will ripple far beyond the mining sector. Building off a collaboration that was first forged in 2021, Caterpillar Inc. has entered into a definitive agreement to supply Nouveau Monde Graphite Inc. with electric mining equipment that will lower the carbon footprint of producing the graphite critical to lithium batteries. In turn, the junior mining company will supply the global heavy...

Since starting electric heavy truck production in 2019, Volvo has swiftly become a leader in the market with a running tally of 4,300 vehicles on the road in over 38 countries, including nearly half of all heavy electric trucks registered in North America last year. Additionally, the demand for zero-emission trucks over 16 tons has increased by 200% in Europe just in the last year, and Volvo Trucks holds the highest share of that market. Volvo currently offers the... Full story

5 MWh battery designed by WAE for Liebherr haul truck charges in only 30 minutes. Australian iron ore miner Fortescue has received what is likely the largest electric vehicle battery in the world – a 1.4 megawatt-hour behemoth designed to power a 240-metric-ton mining haul truck it is developing in partnership with equipment manufacturer Liebherr. This massive 15-metric-ton battery – measuring a whopping 11.8 feet (3.6 meters) long, 5.2 feet (1.6 meters) tall, and 7.9 fee... Full story

To lower the carbon footprint of its electric motors and other products that play a major role in allowing mining and many other sectors of the global economy to then lower their carbon footprint further, ABB is building a strategic partnership with Swedish mining and smelting company Boliden for low-carbon copper. Copper is a vital material for manufacturing the electrical equipment that is playing an increasingly important role in industrial applications that are...

To build team of experts focused on accelerating decarbonization of mining through electrification. Switzerland-based ABB and Australia-based Perenti Group have forged a partnership focused on establishing strategies that will help their mining clients achieve net-zero carbon emissions at operations around the globe. ABB, a company that has been electrifying mines since delivering the first drives and controls to a mine in Sweden in 1891, brings more than 130 years of...

Demonstration of Cat 793 Electric mining truck; new mine site of the future to be built at Tucson test site. With executives from some of the world's largest mining companies on hand to witness the historic event, Caterpillar Inc. carried out its first demonstration of a battery electric 793 large mining truck prototype at the heavy equipment company's proving grounds south of Tucson, Arizona. Roughly as tall as a two-story building and capable of carrying nearly 500,000...

Toward the goal of producing zero-carbon copper at its McIlvenna Bay mine project in Saskatchewan, Canada, Foran Mining Corp. has ordered a fleet of 20 battery-electric underground mine trucks, loaders, drills, and other equipment from Sandvik Mining and Rock Solutions. This US$32.4 million (330 million Swedish kronor) deal marks the largest single sale of Sandvik's growing line of electric mining equipment. "This record contract is the culmination of a year-long...

With the goal of developing a carbon-neutral open pit mine at its Blackwater gold project in British Columbia, Artemis Gold Inc. has cut a deal with Caterpillar Inc. for the future delivery of electric haul trucks. Located in Central BC, the Blackwater Mine is forecast to produce roughly 7.5 million ounces of gold and 40.4 million oz of silver over 22 years. A feasibility study published last fall details an open-pit operation that will be developed in phases – starting off a...